What do you do when life hands you 100 gallons of cider?

You make hard cider, of course.

When I told the kids I was making hard cider they asked how you harden cider. So the process is now known as “hardening.”

The first step is cleaning and sterilizing our equipment. If we have learned one thing from dry aging meat, and fermenting vegetables, it is that cleanliness is the most important step. Even more so than with canning, where everything is going to be sterilized by heat and pressure during the canning process, in fermentation we are relying on microbial populations to do the work for us, and we cannot see those populations. We cannot directly control this process. We only know that certain populations favor one set of conditions, and other populations favor other sets of conditions. The whole trick of fermenting food can be boiled down to

- Keeping the setup and material clean, to reduce the populations of potential unwanted microbes.

- Setting up the environment to support the microbes we want (temperature, sugar content, salinity, pH, etc).

- Add in the source of the microbes that we want (This can be more or less formal, such as adding a cabbage leaf to provide lacto fermenters all the way to laboratory isolated strains of brewer’s yeast).

So we sterilized the glass 1 gallon jugs and all the equipment with a no-rinse oxidizer and scalding hot water.

Then checked the specific gravity. This proved to be a challenge because the half-gallon jars are almost not deep enough for the hydrometer to float. It actually rests on the bottom of the jar.

So I had to pour out most of the clear cider, and then remove the mother from the bottom of the jar, and then combine a couple of jars into one to fill it almost to the top of the jar. This was just barely deep enough float the hydrometer, but I was able to get an initial reading of 1.056.

This was at a temperature of 73 degrees. The hydrometer is calibrated to 64 degrees, farenheit , so I had to use a conversion table, which yielded an initial SG of 1.058. Minimum initial SG is 1.050, so we are in good shape. SG is a surrogate for the amount of dissolved sugars in the cider. If there is not enough sugar in the cider to feed the yeast, it will not ferment to a high enough alcohol content to preserve it from spoilage bacteria. If that is the case, we need to add a little extra sugar prior to fermentation so that the yeast has something to work with. 1.050 yields a potential ABV of around 6%.

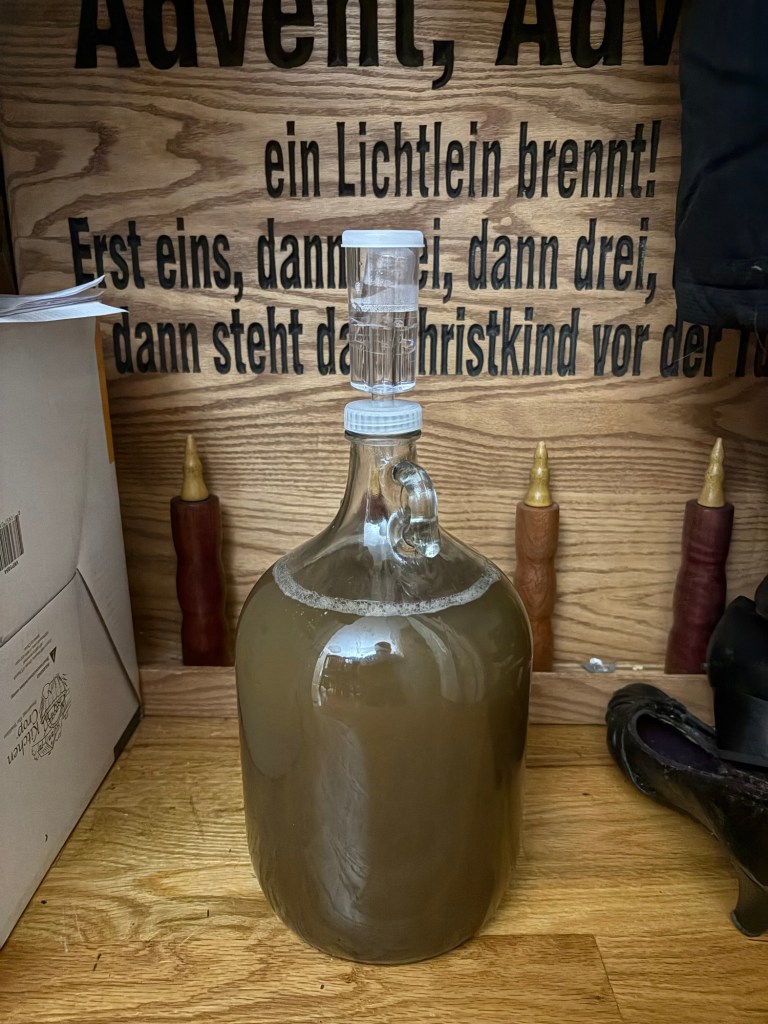

Our cider is 1.058, plenty of sugar, so time to pour it into the primary fermenter (Sterilized funnel and jug).

Pectic acid is an enzyme that breaks up the flocculant that is produced by the yeast. It doesn’t affect the flavor, but it makes the final product clearer and less hazy.

Our cider is made from sweet apples. This is not necessarily a bad thing, but most traditional hard ciders were made from apples that were not fit for eating directly. They were made from sour apples, like crab apples or green apples. This resulted in a complex, tangier final product. We can mimic that by adding tannins, and since I had some that came in the kit, I said why not.

Cider doesn’t always have all the vitamins that yeast likes to have available, unlike wine, so I added some yeast nutrients.

Then finally, some yeast. This is a wine yeast, but it is all I had so it will do for an initial test batch. If make more batches I will buy some cider specific yeasts.

Finally, attach the (sterilize) air lock and put it in the hall closet to do its business.

Now we monitor it to see how much and how rapidly the air lock is bubbling, and when it slows to a stop, then we will transfer to secondary fermentation.

Stay tuned.