Just another normal Monday at the house/farm/homeschool.

Bread is in the oven.

The dibbuns made the two smaller ones.

Critters are doing their school.

Let’s check on our science experiment…

So, there was a bit of a complication with the last batch of hard cider. After we transferred it to secondary fermentation, a day later when we checked on it, it was green!

Not emerald green, or shamrock green, you understand, but with a definite sea green tinge to it. The next day it had become almost black. However, by the fourth day after transferring it have begun to clear slowly back to brown. There by now there is a greenish tinge in the very topmost part of the jug, but the lower half is all brown in color.

We don’t know what to make of it. At first I was concerned it was metal contamination because one of the cider press has cast-iron grinders. This may still be the case, but that isn’t supposed to be reversible.

It might also have something to do with oxidation of the alcohol to aldehyde. A lot of air got mixed into the cider during transfer (there was a leaky gasket in the siphon starter) so this is very possible. Or maybe we didn’t wait long enough after cleaning the jug, since we use an oxidizing agent to sanitize the jug and equipment.

We are going to let it sit for a few more days and take another look.

In the meantime, we decided to make some more, this time with unpasteurized “raw” sweet cider.

So we ground up 30LBs of cheap apples from the local reclaimed produce shop, as well as about 10 Lbs of our last remaining quince from the season.

And we pressed it out.

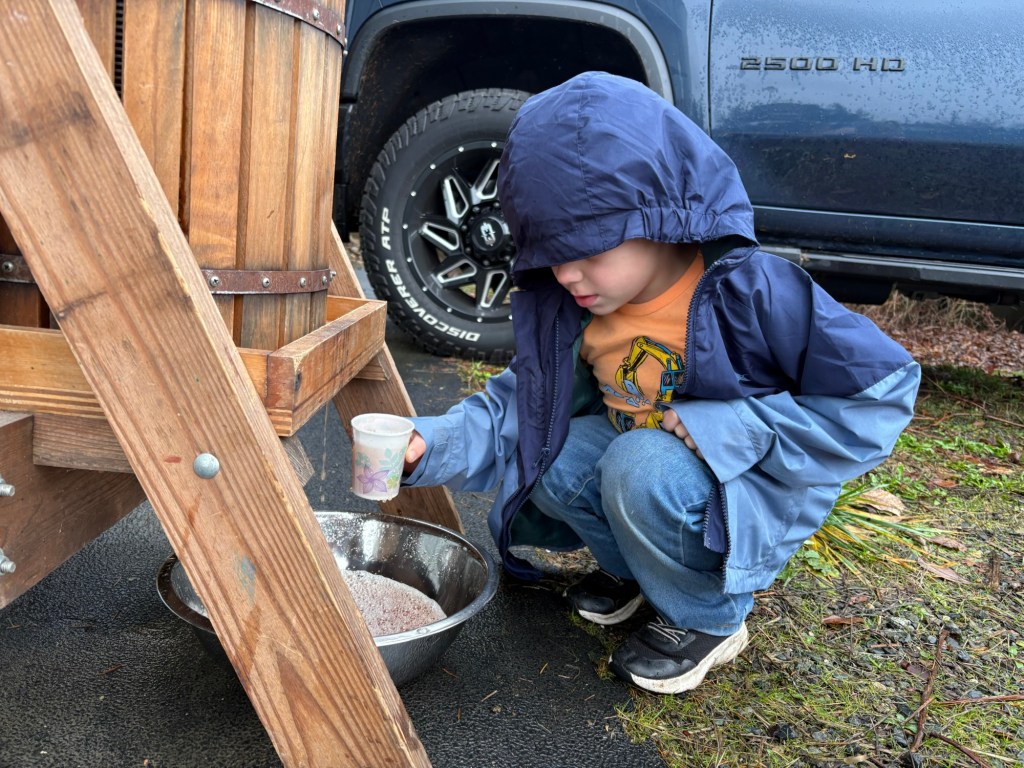

The three younger kids got in on this.

Especially the tasting part.

Where is Evie, you ask?

In the shop gym, doing school. Don’t worry, Ellie will bring her a cup of cider so she can join in.

This is the price of scholastic excellence. Or daydreaming your school day away. Or both.

We have to keep tasting as we go, to make sure that it keeps tasting nice.

Winnie probably tasted more than anyone.

But that’s okay because she is making more.

Spoiler: the crank is actually doing nothing right now.

Latin must continue, cider or no cider.

Seppi’s favorite part is hosing everything down afterwards.

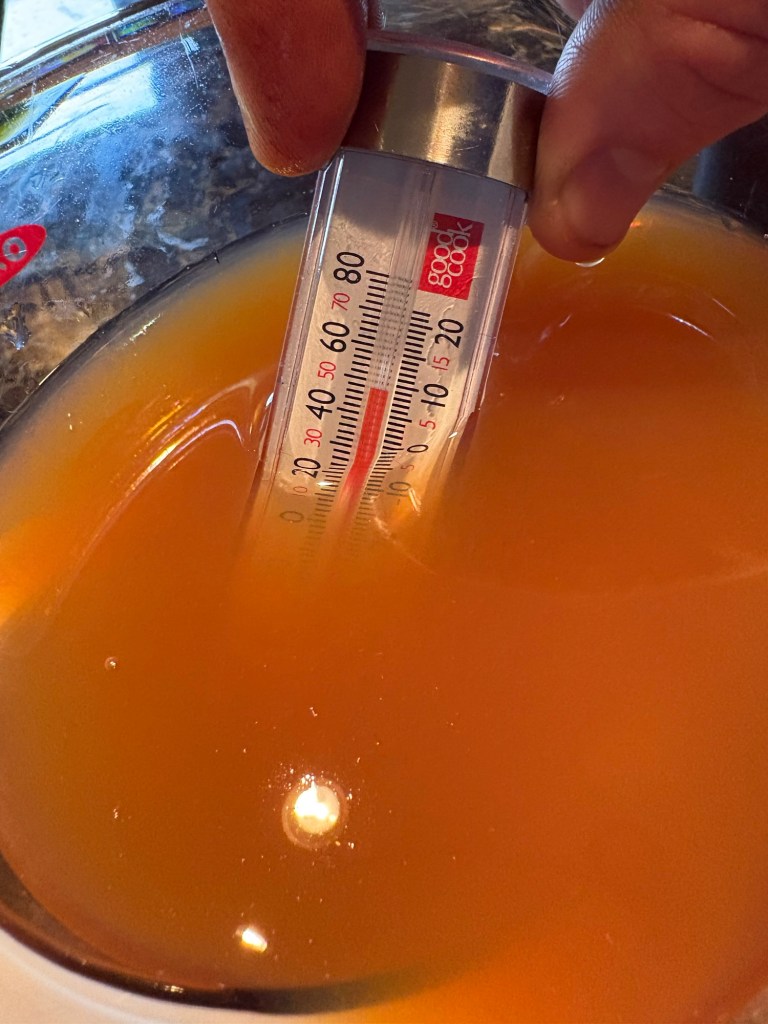

This cider had a little lower sugar content than the previous cider. It read 1.050 raw.

However, the temp at the time was 58 degrees F, so with the temperature conversion factor, initial SG is probably 1.051. On the lower end, but still within a usable range.

For this batch we are doing a more natural cider, so I left the cider un pasteurized, and added no yeast food. I did not even add sulfites to kill the natural yeasts. The only thing we added was a commercial red wine yeast.

Similar to planting seeds in the pasture after a disturbance to encourage the populations of wanted plants to overgrow the populations of the unwanted, the reason for adding this yeast is to make sure that the dominant strain in the fermentation process is a known, useful fermenting yeast. This might not be necessary if we get to the point where we are crushing apples from our own farm, through our own equipment. This will eventually encourage natural yeast strains to predominate in the cidering rooms and cidering equipment. But with store-bought apples I didn’t think it was worth the risk of getting a nasty tasting or even spoilage producing strain.

As you can see, a few hours later, yeast is starting to multiply on the bottom of the container.

4 days later there is vigorous yeast activity with a scummy layer on top and lees forming on the bottom.

Give it a week or two, we’ll check back in when we move it from primary to secondary fermentation.