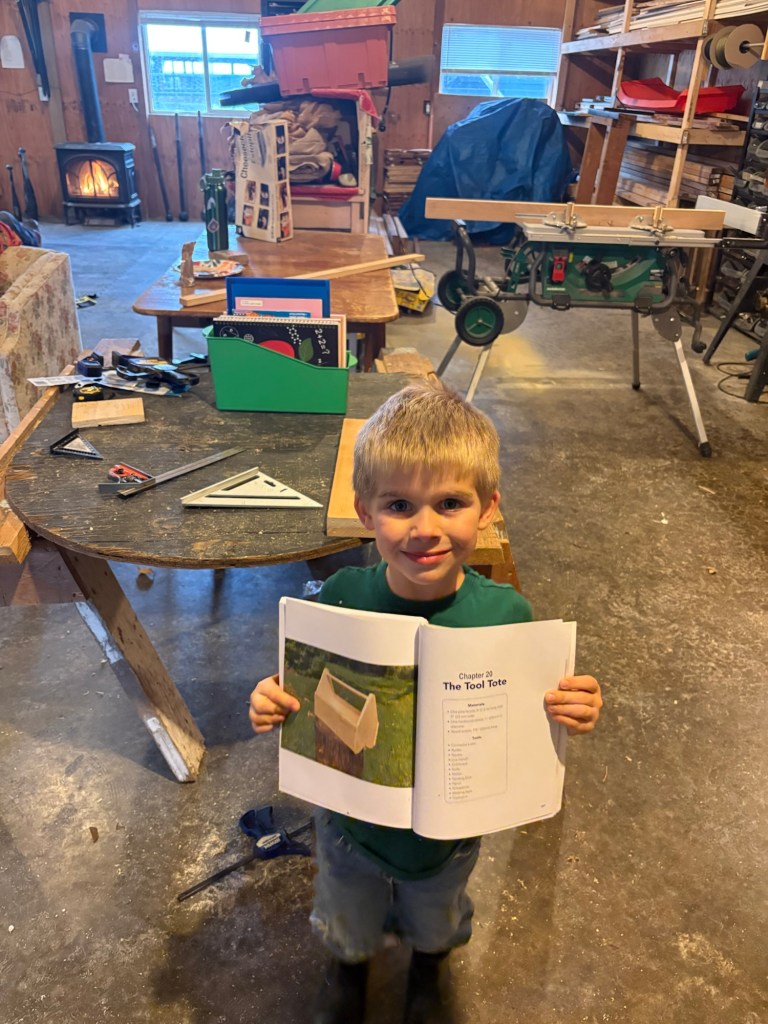

Recently we bought Seppi a new book called “Everyday Woodworking” by Youtube woodworker Rex Krueger. This is because he has been showing more and more interest in building stuff with wood. For example, last week when we got to the farm and started school, Daddy was too busy to help Seppi with his schoolwork for the first hour or so, so Seppi was in charge of his own education. He chose to educate himself on cutting wood with a hand saw.

So we decided to begin a project from his new woodworking book.

Rex Kruger does primarily hand tool wood working which allows more leeway for a small man to do small projects safely.

And since he doesn’t have a tool box right now (we had to move all his tools into a cardboard box when we cleaned up for cider fest) the tool tote seemed like a good first project.

Like shoveling is to farming, sawing is to carpentry. Sawing is hard work, and takes some time and concentration. It is easy to think of it as just something to get through so we can get to the more interesting part, which is putting the thing together.

But good sawing (and good measuring) make good builds. You cannot rush through the measuring and cutting and expect your project to go together well, as we found in this project.

So Seppi spent an hour or so after school cutting the pieces for the tool tote.

And then on Thursday we came back in the morning and spent another hour or so finishing all the parts.

For most of the cuts we used a cheap contractor’s saw that I have had for 20 years or so. I did not use it much in that time, so it is still sharp. It is a modern, “disposable” saw, made with hardened steel and hard, brittle, aggressive teeth. These teeth come from the factory wicked sharp and very hard, but for that reason are difficult to sharpen and impossible to set. If you try to set them the metal is so hard the tooth is likely to break off. Nevertheless, it is a very effective saw for quick cross cuts.

Even for these angled cuts 45 degrees across the grain, it worked very well.

However, these long cuts at 25 degrees, running almost parallel to the grain, it was far less effective. For this we switched to an old rip saw. This saw has large teeth with straight, almost chisel-like shape, rather than the tapered, knife-like shape of the crosscut saw. This makes it more efficient at plowing along the grain.

The best part is that this saw has the C. W. initials on it. This means is belonged to Papa Jerry’s dad, Grandpa Carl. Old as dirt, but still one of the best saws in the shop. These older saws are made of much softer and tougher steel, which, while not as sharp the modern contractor’s saw, can be resharpened and re-set, and even if necessary completely re-toothed in an ordinary workshop. With care, Seppi’s grandson’s could build things using this saw.

We could, of course, have busted out the dewalt for the handle holes, but a forstner bit in a bit-and-brace is surprisingly fast and effective. It was almost more than Seppi’s muscle could handle just yet, but he pushed through and got it done, and this makes him stronger, and helps him develop his eye and hand far more than me zipping through it with an electric drill would do.

Then we rounded over the corners of the end pieces using a coarse rasp, and then filed down the tooth marks with a file, before taking a piece of sandpaper to it. This is a rough, utilitarian piece, and it is being built by a five-year-old. Glass polish surface is neither necessary nor helpful, but getting the edges rounded over so they don’t scratch or get caught on clothes or such.

And Seppi thought it was fun.

Finally, he cut through the red oak dowel that was intended to make the handle.

All the pieces cut out.

And packed up, ready to go up to Enumclaw.

Halloween we were up at Enumclaw in Papa’s shop. Seppi wanted to finish this with Papa, so we brought all the pieces up.

Attaching the cleats.

Glue and screws on everything.

Oh, this is where we learned not to rush things. When we brought the pieces up we accidentally grabbed the wrong half of the handle dowel, which was too short. So Daddy ran down to the hardware store (dressed as Mr. MacGregor) and grabbed another 1″ dowel, but then he measured too hastily and cut it too short. So then Mommy had to run to the hardware store (dressed as Mrs. McGregor) to get another one.

Then we were finally able to put the darn thing together.

And there it is! Seppi’s tool tote. Also his trick-or-treat basket.

Flopsy, Mopsy, Cottontail, and Peter Rabbit (check out the blue jacket with brass buttons that Mommy made for her naughty little bunny). In the background you can see Mr. MacGregor, who chases bunnies with a rake, and Mrs. McGregor, who puts them in a pie.