Caution. This post is about where food comes from. Proceed accordingly.

The meat ducks reached a healthy (and hefty) 8 weeks old, averaging 8.4 Lbs (this might be a slight overestimation, as they sometimes bounce around in the bucket while being weighed). We ordered 20 ducks from Meyer hatchery, they shipped 21 on April 7th. They arrived on April 7 in good health. One declined and died within the first week or so, but the other twenty made it to full growth. The smallest were 7.5 Lbs and the largest was 9.5 Lbs (bit of an outlier).

We started the butchering on Thursday, March 29. The plan was initially to slaughter and pluck as many as possible on Thursday, refrigerate them over to Saturday, then butcher and freeze on Saturday.

Oh, and also the two geese. This is the second year with no goslings, so the geese have been consigned to the freezer.

When we did ducks last year they were all heritage breeds, and 6 months old at time of butchering. Scalding them was not particularly helpful as the water just ran off the outer feathers and didn’t touch the inner feathers. If we left them in the boiling water long enough to get through the outer feathers, the skin got soft and tore off too easily. Most of them plucked pretty cleanly simply dry plucking, and the plucker didn’t seem to do more than just batter them around and tear the skin, so I thought we would try dry plucking with the Grimaud Pekins.

This was not a good idea. First of all, it started raining fairly heavily so we had to move inside the shop. The dry feathers refused to stay contained to the tarp and started blowing all around the shop.

Secondly, the pekins have 10 times more down than the heritage ducks. The number of pin feathers was extremely small, but the down was just as troublesome. You can dry pluck a pekin if you are very patient and have strong fingers. Dry plucking twenty in one day is just not in the cards.

We tried scalding them after the outer feathers were off, and this helped make the down feathers easier to remove, but the plucker still wasn’t all that helpful. It just doesn’t grab the small downy feathers very well, and if you leave them in the plucker too long it starts tearing the skin.

Our parish priest came out to help with the process as well. So that’s kind of awesome.

After the first 5 or 6 ducks, Kathleen and the kids came back from swimming lessons to join in the fun. Mommy was not quite satisfied with the pace of the process, so she did some more research on scalding and plucking. She found that people who process ducks are sometimes scalding them for 1-2 minutes before throwing them in the plucker, which blew my mind. But it was either that or start skinning them all, so we turned the flam back on under the water and tried it. It worked beautifully for two ducks, but then started tearing skin on the next couple, as the water approached boiling, so Kathleen did some more searching and we learned that the ideal temperature for scalding a duck is between 150 and 160 degrees F. Once we started shooting for that target, things started going much more quickly, and we got 12 ducks and two geese butchered before 3 PM.

By this time it was pretty much closing time. We could maybe have pushed through and gotten the last eight ducks killed an plucked, but we didn’t have the refrigerator space for them, so we decided to shift gears and get the birds we had already plucked cleaned and in the freezer.

That is a relatively quick process, but it still took another few hours to get all of them packaged.

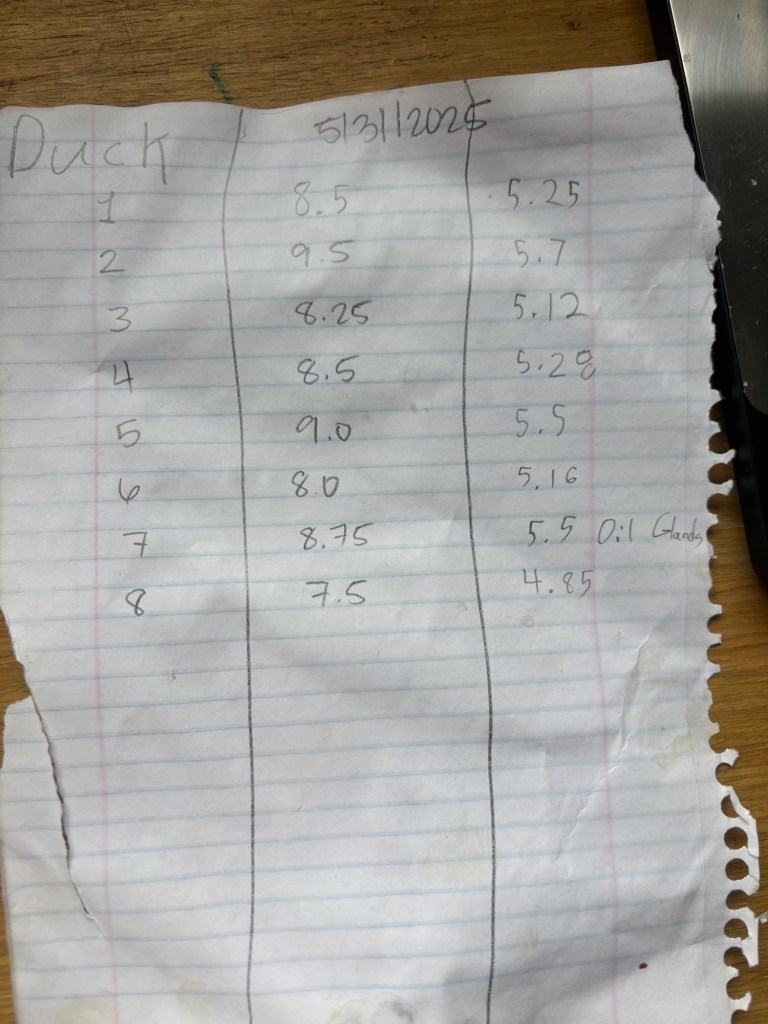

Day one weights, before and after processing. The average weight lost in processing was a little more than we had projected, 38% vs. 30%. This is likely because we did not include hearts, livers or gizzards in the final processed weight.

Saturday morning we were off to a slow start, but Uncle Cole came out to help us and we only had 8 ducks to do.

This time we started right off the bat with the scald water going at 150-160 degrees and scalding the ducks for 1-2 minutes. The feathers came off much more smoothly. We found that the ducks like to float belly-up in the scalder, and if you plunge them in and out repeatedly until they sink, this does a better job of getting through the inner layer of down feathers. They also like to flip belly-up in the plucker (which, incidentally, works better if someone is spraying them with a hose) so often the backs came out almost clean while the belly needed a little extra work, and the “armpits” and hollows under the thighs were almost completely untouched.

Still, it went very quickly, and we were actually able to take a nice, relaxing lunch break before we got on to cleaning and packaging.

Evie is turning into quite an effective butcher. There are some nuances about removing the guts that she hasn’t got down yet, particularly in the ducks who have a long, narrow body cavity compare to a chicken, but in a year she will be able to handle a duck or a chicken all by herself!

This was suppose to be a timed run, but…

My phone spontaneously shut off. It’s been doing that a lot lately. The dozen or so fracture lines across the back that allow it to bend in the middle might have something to do with it.

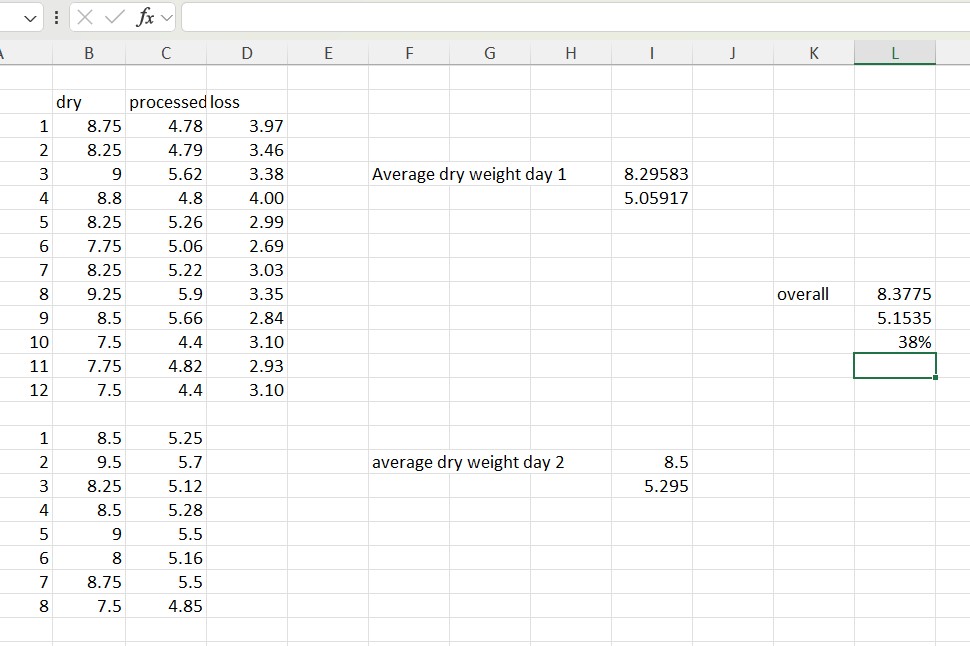

Day two weights.

It is going to take a while to get all these feathers cleaned up.

Actually, it didn’t, because when the kids found out they got to play with the shop vac, they made a game of it on Monday morning and cleaned them all up in an hour.

Final numbers:

Total cost to raise was $27.57 per duck, or $5.35 per pound. Carcasses weigh between 4.4 and 5.7 Lbs, with most being right around the 5 Lb mark. 16 were deemed clean and pretty enough to be frozen whole, while four were partially skinned and cut into pieces for confit and prosciutto experiments.

Some lessons learned:

- 20 ducks is the max number per run we can fit in the shade-mobile. Getting them on the pasture earlier, possibly behind the cows so they can be inside paddocks and be allowed to forage more safely, would be good, although aerial predators are a big concern.

- The compressed bedding pellets work well, but thinner layers more frequently are better than a few thick layers.

- Getting started on butchering days, 8:00 AM is better than 9:00 AM, because there is a good 45 minutes to an hour of set up.

- Having more refrigerator space would be helpful. It really would have been more efficient use of time to kill and pluck all 20 birds on day one, and then clean and package them on day two.

- Maintaining 160 degrees water temperature with a propane burner is tricky, and easy to lose track of, then next thing you know you are parboiling the birds. Maybe invest in an electric scalder that easily maintains the temperature? Especially since we are planning two runs of Cornish Cross later this year, so the cost could be spread over other runs of birds besides just the ducks.

- Even with the scalder and plucker fully dialed in, the down feathers are tedious and some of them remain on every bird, because it just isn’t worth the hours of work it would take to get rid of all of them. Next year, for the ducks specifically, invest in duck wax to get a cleaner pluck with less effort. This will increase the cost of ducks specifically since I don’t think we would necessarily use it for chickens.

So that was our first run of dedicated meat ducks. Stay tuned for more great adventures in pastured poultry and other critters.