Well, folks, our second annual Ciderfest was a great success. And now that we have done a second one, I think we can actually call it annual. It takes two data to create a vector, don’t you know?

“Here you go, Daddy!” Dixie cups for tasting the fresh squeeze. Let me tell you, there is no more delicious cider than that which comes directly from the press. It is pure apple, unpasteurized, and about 3 seconds old which means none of the sugar has had a chance to oxidize yet (at least, that’s how I explain it. It makes me sound sciency.)

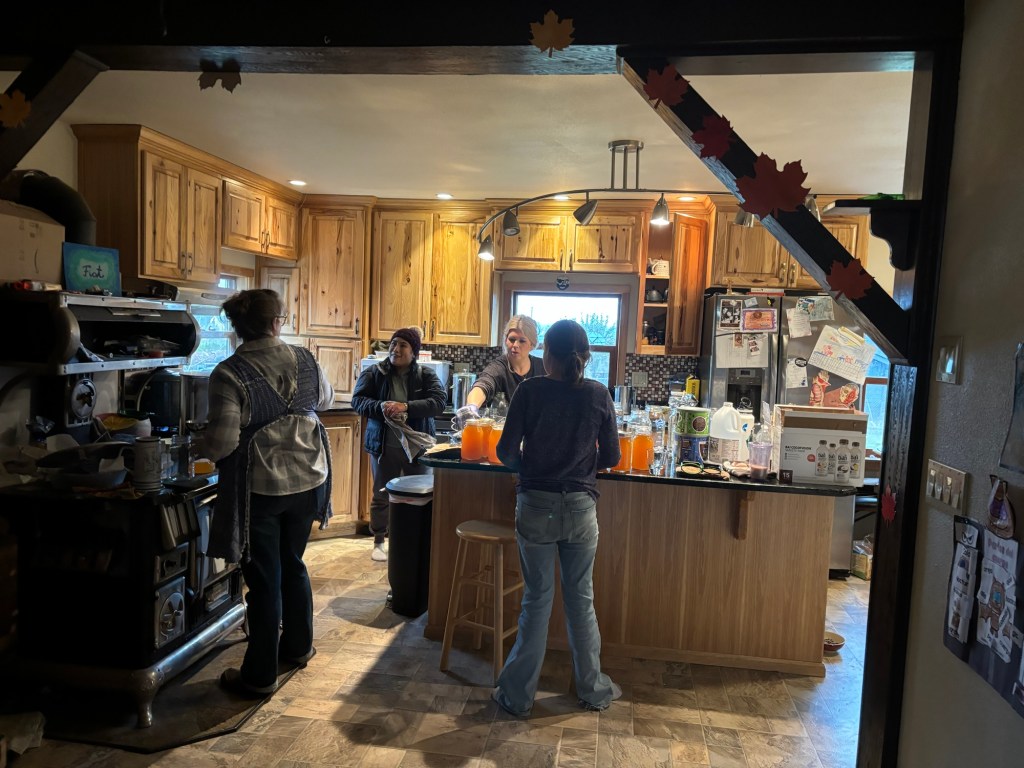

Making soup for lunch. Everything in that minestrone soup, except the tomatoes (off year for those), came from our garden. We also set out some home-made mincemeat muffins, and a box of chips for the uncultured, a.k.a., the children.

Some of our friends from 4-H brought apples and a 3-burner propane stove (halleluiah!) and then the pressing commenced.

Once it got started we were too busy for taking pictures. We are really bad social-mediators.

The pressing is, in many ways, the easy part. It was done by about 2:30. The canning is the most important piece of the operation. It doesn’t matter how much cider you can press out (we ended up making 55 gallons from an estimated 1000 Lbs of apples) if you can’t preserve it. If not sterilized and canned it will turn into vinegar very quickly.

This year we were fortunate to have the three burner stove and the help of a team of very capable ladies. The propane stove allowed us to keep three pots of cider heating simultaneously out on the front porch. It is the heating of the cider that is the slowest part of the process. It has to be brought from roughly 45 degrees (the temperature of the apples in the pile) to 190 degrees F, ideally without boiling as this can change the flavor. The hot cider is then ladled into hot jars which are then submersed in boiling water for 15 minutes, a.k.a. water bathing.

Last year we had only two stove tops and a turkey boiler going. One of the stovetops was dedicated to heating the cider, which meant less cider ready, less space to water bath, and a slow overall process with lots of dead time waiting for one or another process to complete. This year, with the propane stove that freed up the other stovetops for water bathing, allowing the ladies to move quarts through in multiple batches of 5-7 each. We also bought a large 10 gallon stock pot for the turkey boiler, which could handle 5 half-gallon jars at once instead of three.

Good cider haul, and an even better community day, thanks to the friends who came out an helped.

The requests for next year were ale, a live band, and a porta-john.

We’ll see what we can do.

2 thoughts on “Ciderfest 2024”